Specification and Performance

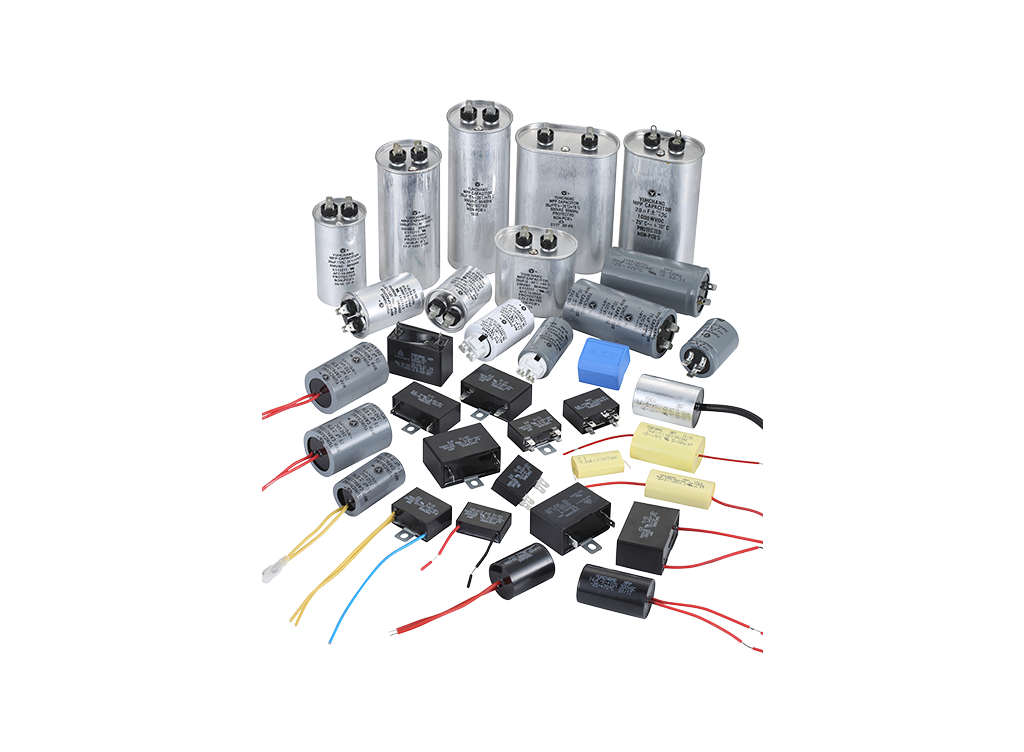

| Motor Running Capacitors |

Lighting Capacitors |

|

| Standards |

IEC 60252-1; CNS 4327; JIS C 4908 |

IEC 61048, IEC 61049; CNS 4327; JIS C 4908 |

| Application | For motor starting and running of air conditioning machines, refrigerators, washing machines, ventilators, electric fans, etc. | For use in tubular fluorescent and discharge lamp circuits. |

| Usable altitude | Max above sea level 2000M | Max above sea level 3000M |

| Frequency | 50/60Hz | 50/60Hz |

| Tolerance | K(±10%) U(+10% ~ -5%) J(±5%) | K(±10%) U(+10% ~ -5%) J(±5%) |

| Operating temperature | Minimum temperature: 40°C or -25°C | Minimum temperature: 40°C or -25°C |

| Maximum permissible voltage | 1.1 x rated voltage | 1.1 x rated voltage |

| Maximum permissible current | 1.3 x rated current | 1.3 x rated current |

| Maximum permissible output (kVAR) | Rated kVAR x 1.35 | Rated kVAR x 1.35 |

| Dielectric | Polypropylene (PP) film or Polyester (PET) film | Polypropylene (PP) film or Polyester (PET) film |

| Dissipation factor ( at 20 °C 60Hz) | Dielectric PP: < 0.1% Dielectric PET: < 0.3% | Dielectric PP: < 0.1% Dielectric PET: < 0.3% |

| Test voltage between terminals | Applied rated voltage x 2 VAC for 2 seconds | Applied rated voltage x 2 VAC for 2 seconds |

| Test voltage between terminals and case | Applied rated voltage x 2 + 1000VAC (minimum 2000VAC) for 1 minute | Applied rated voltage x 2 + 1000VAC (minimum 2000VAC) for 1 minute |

| Insulation resistance | Above 2000M Ω between terminals and case | Above 2000M Ω between terminals and case |

| Discharge character (Only for capacitor with discharge resistor) | The residual voltage drops to 50V or lower in 1 minute after capacitor being disconnected from power source. | The residual voltage drops to 50V or lower in 1 minute after capacitor being disconnected from power source. |

| Safety (Only for capacitors with safety mechanism or protective device) | 1. Safety Mechanism: Capacitor elements adopt metallized polypropylene film with field optimization designed, when element had internal failure, the fuses of failure segments would blow to block the segment failure area from power source. The reset normal segments can keep capacitor working well. 2. Protective Device: The protective device will disconnect the power supply in case of internal failure with overload and failure protection. 3. Protective Device: Device to protect the capacitor from external power line over-current (pressure sensitive interrupter) with overload and failure protection (P2 according IEC 60252-1, AFC 10000A (according standard UL 810)). | 1. Safety Mechanism: Capacitor elements adopt metallized polypropylene film with field optimization designed, when element had internal failure, the fuses of failure segments would blow to block the segment failure area from power source. The reset normal segments can keep capacitor working well. 2. Protective Device: The protective device will disconnect the power supply in case of internal failure with overload and failure protection. 3. Protective Device: Device to protect the capacitor from external power line over-current (pressure sensitive interrupter) with overload and failure protection (P2 according IEC 60252-1, AFC 10000A (according standard UL 810)). |

| Quality approval | UL, VDE, RoHS | UL, VDE, RoHS |

| Factory approval | ISO 9001 | ISO 9001 |